The upper tour should be covered with stone slabs, each containing an engraving with symbols (planetary symbols, astrological signs, runes). The circular central building will be surrounded by four square galleries; Each gallery symbolizes an element.

The interior should have an area of around 8,000 m² and should serve as a spiritual center for Syban visitors and Syban members for contemplation, retreat, meditation, and for various celebrations and various rituals.

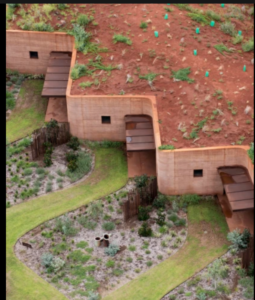

Rammed earth construction

Rammed earth construction (or “Pisé” from French piser, German ‘stomp’, Spanish pisar; English rammed earth) is a massive type of earth building and is fundamentally different from building with air-dried clay bricks. In addition to walls, floors will also made from rammed earth.

Story of Rammed Earth

Already in the Preceramic Neolithic, e.g. B. Rammed earth buildings were built in Jarmo. The technique was used in the Berber regions of North Africa, on the Arabian Peninsula and in the Middle East (tauf), where it is still used in rural areas today, although it is becoming less common. Rammed earth was also used for building in large parts of Europe until the Middle Ages; In modern times, building with clay gradually fell into oblivion – clay blocks and fired bricks replaced rammed earth walls. It was not until the end of the 18th century that the technology was resumed in the form of “loam pisé construction”, which was widespread in Switzerland[1] and France.

The clay wave construction method developed particularly in Thuringia and Saxony, in which the clay is not tamped into the formwork, but rather can be piled up immediately to form a wall due to the higher straw content, the surfaces of which are later cut smooth.

Similar to rammed earth, lime-sand mixtures and cement-sand mixtures were later used to produce rammed floors. See: stamped concrete.

Labor and Works

Depending on the region, approximately 10-40 cm high layers (good compaction is no longer possible with higher layers) of earth-moist clay with a bulk density of 1700 to 2200 kg/m³ are poured between a pressure-resistant formwork and compacted by treading or working with tamping equipment. Compared to traditional techniques, mechanical tamping reduces time and effort. After completion, the formwork can be switched off immediately because – unlike concrete – there is no setting time. However, entering a set that has just been switched off should initially be avoided.

In the case of a rammed earth wall braced by the building’s supporting structure, the wall thickness should be at least one twelfth of the height. A free-standing wall needs to be even wider.

Advantages and disadvantages

The clay and marl mixtures often found in nature can easily be used for rammed earth construction by adding clay, sand, gravel and straw. Rammed earth is one of the most environmentally friendly building materials of all, as only a comparatively small amount of primary energy is required for extraction, transport and mixing. In contrast to building materials such as concrete, fired or steamed artificial stone or steel, resource consumption is kept to a minimum.

In addition, clay is hygroscopic, meaning it absorbs (air) moisture and releases it again, and thus has a beneficial regulating effect on the indoor climate, just like open-pored wood and other natural building materials. Clay can absorb allergenic or otherwise harmful substances from the air in the room.

If the building is demolished or converted, the building material can be stored until it is mixed with water and used again or returned to the landscape from which it was taken.

As was common practice in previous centuries, the thermal insulation value of the building material can be greatly improved by adding fiber materials such as straw, wood wool, wood chips, shavings, sawdust or light mineral fillers such as expanded clay, expanded slate, perlite and the like. A solid rammed earth wall achieves the F90 standard for fire resistance. In multi-storey buildings, it must be checked whether the fire brigade’s extinguishing water could soften unprotected load-bearing walls and impair stability.

Clay is less resistant to moisture penetration and compressive, tensile and bending stresses than other building materials, which limits building designs with delicate or cantilevered components. Otherwise, clay is a structurally sufficiently strong, inexpensive building material.

Surface structure

Clay comes in different shades. The wall can be colored by adding earth pigments.

The surface structure of unplastered rammed earth is of course also influenced by the aggregates and processing. As a rule, it can be expected that the steps created by the layer-by-layer introduction of the clay mixture into the formwork will later be visible as lines.